Kanban Inventory Management: what it is and how it works

Kanban inventory management (or simply Kanban) is a production management method developed by Taiichi Ohno, the industrial engineer responsible for revolutionizing Toyota’s production system. This method led the Japanese company from crisis into becoming a global automotive leader.

But Kanban inventory management system isn’t limited to manufacturing: commercial businesses can also adopt the method, since it can be applied to different industrial processes:

- Production Kanban, to manage material flow between production phase, preventing overproduction and ensuring that workstations are supplied just in time

- Purchase Kanban, to optimize the supply chain activities by replenishing materials based on consumption, reducing the risk of stockouts and overstocking

- Move kanban, to ensure smooth internal logistics between warehouses and departments or work cells

- Distribution/Sales Kanban, to coordinates at best the distribution of finished products to distributors or final customers, ensuring timely replenishment and delivery.

Companies can choose to adopt one or more type of Kanban or all of them (e.g. purchase only, production and movement…) as well as the items to which apply Kanban. The choice depends on various factors, including the type of product processed, consumption frequency and business needs.

How it works

The Kanban inventory management system revolves around several key components:

- Customer and supplier processes

- Standard containers

- Kanban cards

- Material replenishment with Pull system.

Supplier process and customer process

Each Kanban-managed material requires clearly define “customer” and “supplier” processes:

- Supplier, or supplier process: the department or workstation responsible for supplying the material to the customer process.

- Customer, or customer process: the department or workstation consuming the material, the one who must receive it

- Supplier, or supplier process: actor in the material flow responsible for replenishing the requested material. It can be external (e.g. company or other plant) or internal (e.g. warehouse, production department, etc. in its own plant)

- Customer, or customer process: actor in the material flow that owns the material in stock and, upon consumption, recalls it. As with the supplier process, it can be internal or external.

For example, in a suitcase manufacturing plant, the “Handle Assembly” workstation needs handles from the “Central Warehouse” and springs from the “Spring Bending” workstation. To continue the flow, the assembled handle will be transferred to the “Finished Product Assembly” cell, where the assembled handle will be assembled on the body of the suitcase.

In this case, the customer-supplier relationship is the following:

| Kanban managed material | Supplier process – who supplies it | Customer process – who receives it |

| Handle | Central Warehouse | Handle Assembly |

| Springs | Spring Bending | Handle Assembly |

| Assembled handle | Handle Assembly | Finished Product Assembly |

Standardized containers

Kanban-managed materials are organized in standardized containers.

These can be the typical rectangular boxes but also carton boxes and other containers of different sizes and materials based on the type of item managed.

In the case of bulky materials (e.g. sheet metal, glass panels, industrial cables) the containers are represented by crates, reels, pallets or other units.

When selecting the container, you must also establish the number of standard pieces that will go inside for each material.

| Kanban-managed material | Container | No. of pieces per container |

| Handle | Medium yellow type A | 12 handles |

| Spring | Medium yellow type A | 100 springs |

| Casket body | Large box type G | 1 case body |

| Metal sheet | Europallet | 40 sheets |

Kanban cards

On the external surface of each container there is a card attached (via hook, inserted in a transparent pocket or, if printed on adhesive labels, applied directly on the container). This card, called “kanban card” or “kanban”, displays a summary of the information needed to replenish its content.

| Type of information | Example |

| Item code | X1N3401 |

| Item description | Handle for large suitcase

|

| Quantity of items present in the container | 12 |

| Type of standardized container | Medium yellow container type A |

| Name and/or supplier code | MC1 – Central Warehouse |

| Name and/or customer code | AM3 – Handle Assembly Cell |

| Lead Time (delivery times) | 1 day |

| Possible barcode to digitize the transmission of the information contained in the kanban card |

Kanban cards are the backbone of the Kanban Inventory system. The word Kanban itself, which translates into “visual signal” in Japanese, refers to these cards which visually triggers replenishment when needed. Let’s see how it works.

Materials replenishment with Pull system

With the simplest version of Kanban inventory management (there are different types), the material is reordered only when the operator picks up the last piece from the container in use: once the last piece has been picked up, the operator must detach the kanban card on the now empty container and deliver it to the supplier process. The supplier will restore the consumed material according to the information reported on the card itself (e.g. quantity of pieces, container and to which it must be delivered).

As you can see, this is a very simple sequence of operations.

- The operator removes the last handle from the container.

- The operator detaches the Kanban card from the now empty container and send the card to the supplier process

- The supplier process, i.e. the warehouse, prepares the container following the instructions on the kanban card and applies the Kanban card on the new container itself

- The container, with the replenished items and the attached Kanban card, is delivered to the customer process, the Handle Assembly cell

- The operator receives the containers with the handles… and the cycle repeat

As you can see, Kanban Inventory management is a Pull production method: the supplier starts replenishing the requested material only when necessary (because requested – “pulled” – by the customer process that consumed that material) and not because of consumption forecasts, which often lead to overproduction and waste.

Kanban inventory Management Benefits: Less Inventory and Better Warehouse Management

Implementing a Kanban inventory management system, companies align production with actual demand and reach:

- Optimal inventory level, suited to operational needs and without excesses

- Significant reduction in overproduction

- Faster and more effective transmission of orders: the operator no longer needs to wait to receive instructions from his manager regarding what and how much to produce but infers it directly from the kanban cards received.

Important: the optimal inventory level may vary based on numerous factors, including minimum processing/purchase batches and material managing costs. These situations are effectively addressed by choosing the “Kanban management policy” best suited to the individual item (classic kanban, batch kanban, signal kanban or double bin). We will discuss this topic in future articles, but the key point is the same: Kanban inventory management allows you to effectively reduce several problems of “classic” production methods, first and foremost overproduction and excess inventory.

Tools for optimal Kanban inventory management

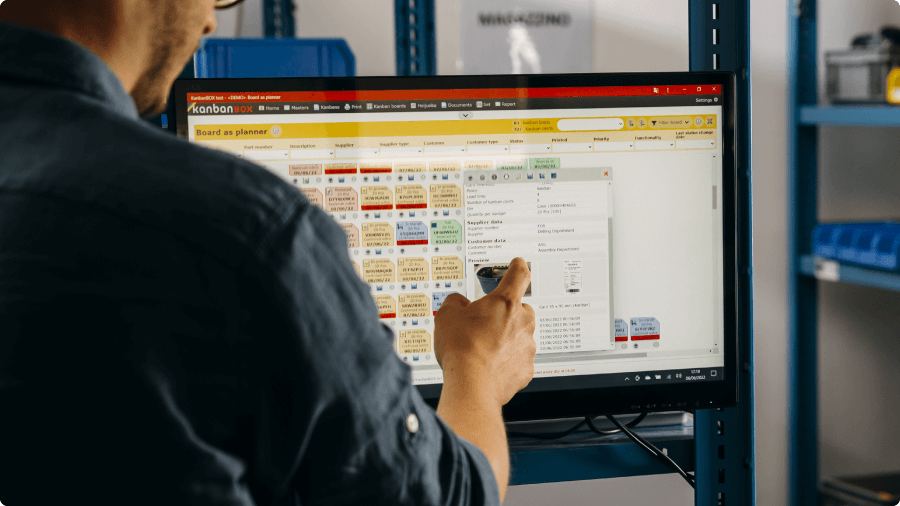

For companies looking to maximize the benefits of Kanban, the best choice is to adopt KanbanBOX, the software which enhances the physical advantages of kanban inventory management with digitalization.

Real-time material flow monitoring

Thanks to its real-time updated dashboard, you have a complete view of the materials’ progress status at every stage of the process, which is essential to better coordinate the distribution of work and the use of machines for more efficient planning and allocation of resources.

Digitalization of replenishment orders

With KanbanBOX, the operators who have emptied a container will no longer need to physically detach and deliver the kanban card to the process supplier. They can simply scan the barcode on the card with a smartphone or scanner and the replenishment order will be immediately transmitted to the supplier process.

Automation of reorder requests from external suppliers

Without KanbanBOX, the Purchasing Manager must collect all the cards relating to a supplier, check whether they have reached the minimum order quantity and write an email to the supplier with the list of codes to replenish, repeating the operation for all the numerous suppliers. With KanbanBOX, the software records all the replenishment requests coming from the central warehouse or the production lines and, once the minimum order quantity has been reached, automatically sends the pre-authorized order requests. In addition, KanbanBOX can be integrated with your company management system, to keep the data aligned in real time on both systems.

Kanban inventory management with KanbanBOX

Implementing Kanban inventory management for one or more phases of the production/commercial process is a smart choice. Here’s the proof:

- Both our studies and reports in industry magazines show important results, including a reduction in inventory with an average of 20%-50% or more depending on the starting conditions

- The ever-increasing number of companies, both large and small, that decide to adopt this method

Among the large international companies that use Kanban for materials management, there are, in addition to Toyota, which invented the method, also Amazon, Boeing and Harley-Davidson.

Do you also want to join the most cutting-edge companies? Contact us!

We will show you what results you can achieve by implementing Kanban inventory management, with or without the KanbanBOX software!