KanbanBOX for healthcare

KanbanBOX for the management and the control of the MD process

Focused on people

A wasteless and functioning hospital service, that aims to achieve efficient, complete, and punctual management of the Medical Devices supply cycle is no longer a utopia. From Lean Manufacturing to Lean Healthcare: KanbanBOX is the material optimised management electronic kanban software specific for Healthcare.

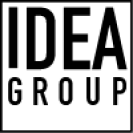

KanbanBOX is an immediate, for-all, easy-to-manage, and to-use visual platform. The software sets a unique working standard: when everyone works in the same way, every day, and the pharmacy and the supply areas are designed, organised, and arranged to ease the workflow, everything ends up being lean, standardised, and efficient.

Focused on people. Thanks to the nursery workflow improvement, it is possible for health workers’ time to return to carrying out the only high-value added activity: patient care. Discover the benefits of KanbanBOX for Health Authorities!

Management benefits of the web software

By eliminating stock excesses and the risk of stock outs, a lack of material and obsolete supplies, the relevant space management costs, and the traditional supply process distribution logistics costs, systemic benefits increase, spendable in core activities. Clinic workers can concentrate on their patients, and administrative workers on data and performance measurement to create a structure that can be a real innovation and excellence centre.

- Warehouse costs, logistics, administrative transitions

- Consistent purchases, optimised flows, availability, human error elimination

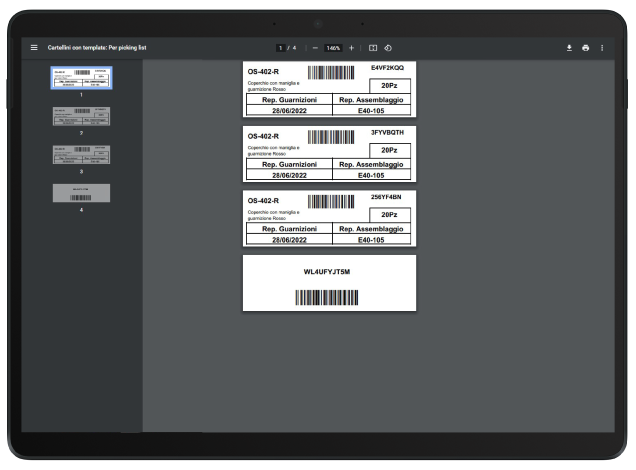

- Traceability, expiry date management, batch control, stock out risk elimination

- Low-value activities elimination, workers’ satisfaction, and motivation increase, and better performance

- Consumptions are based on effective productivity, monitoring, consumption transparency, and reports

- Use of cutting-edge technology, Service management, increase in centre excellence.

Costs reduction

The application of visual management, supply processes and healthcare goals in the Hospital sector result not only in cost reduction, organisational efficiency, process maximization and rationalization but also and especially in the real return to patient centrality from a Service management perspective for the health system.

Resources management

KanbanBOX supports the technical-organisational management profiles to which the governance of strategic change in the health sector is entrusted, with a specific focus on innovation management and value production, resources optimisation, rationalization and waste reduction according to a Lean approach: topics that are absolutely relevant within the international and national health scenario.

Efficiency

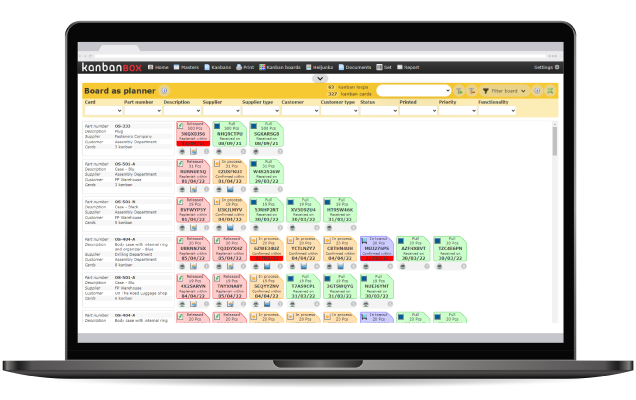

Throughout the entire pharmaceutical and Surgery room, Specialties and Logistics Centre, and Surgery Procedure Medical Devices supply cycle management, KanabanBOX allows material rationalization and traceability throughout the whole clinic process.

Innovation

Thanks to the electronic kanban (e-kanban) Pull organisation, it is possible to establish and standardise the warehouse and orders management process, normally characterised by a series of routine activities that cause time and resources loss at the expense of strategic and administrative activities, medical and nursery workers care. The results consist in a reduction in lead times and their variability, easy planning, patient response and higher reliability of supply services issuing times, easing the hospital itinerary.

Discover The Healthcare Case Study

Stop the unproductive activities that burden nursery workers. More motivated workers, happier patients! The Centre Oscar Lambret is a French hospital that implemented the electronic kanban to align their stock with the real needs. They succeeded in making the replenishment process more efficient.

Lean Management for healthcare

The application of the Lean Management principles of KanbanBOX software in a hospital context, emphasises the principle of the focus on human beings within the processes, returning quality time to nursery and administrative workers jobs, relieving them from all those non-core and low value activities that are expensive in terms of time: orders, invoices, delivery notes, goods acceptance, control, distribution…

By eliminating non value added activities and reducing the time of those with no value added, but which are in any case necessary, the outcome is a system able to provide the best possible service for patients.

Supporting strategic and operative choices aimed at costs, standard costs, analysis, and costs centre innovative management, KanbanBOX becomes the indispensable tool for doctors, operators, administrative executives, health authorities and health trust accountants and managers; health authorities and health trust managers, health authorities, private and public hospitals, diagnostic centres, polyclinics and care homes.

KanbanBOX is a Visual Management lean tool that is indispensable for standardising procedures and workplaces, that pays attention to the processes much more than to individual activities.

Thanks to the standardisation of non-value added activities, workers’ work quality increases significantly, increasing the focus on core activities, creating satisfaction and motivation. The outcome is a virtuous reconstruction of different health productive process moments according to the patient itinerary.

With a simple tool, it is possible to face different health system mismanagement problems: financial deficits, organisational dissatisfaction, waiting list problems… Efficiency is a fundamental parameter for health authorities, and that is why flow optimisation becomes an indispensable perspective to achieve any improvement!