The best integration for Material and Inventory Management

The partnership between ONO Lean Logistics and KanbanBOX

In today’s fast-paced manufacturing environments, efficient material flow is crucial for staying competitive. KanbanBOX and ONO Lean Logistics bring complementary strengths to the table, addressing distinct aspects of material handling to help companies reduce waste, enhance productivity, and align with Lean principles.

What is KanbanBOX

KanbanBOX is an electronic kanban inventory system built to manage material flows and inventory in real time. By applying the kanban methodology to electronic tracking, it ensures that materials are available in the right quantity and location throughout the production process, reducing the need for large warehouses. KanbanBOX allows companies to set up “supermarkets” or smaller storage hubs that support a just-in-time approach, optimizing resources and avoiding the pitfalls of excess stock. With real-time data and easy integration into existing systems, KanbanBOX simplifies inventory management across the entire supply chain.

What is ONO Lean Logistics

ONO Lean Logistics redefines traditional warehousing with an intelligent storage and retrieval system designed to bring materials as close as possible to the operator. It differs from automated warehouses by emphasizing ease of access for operators, delivering materials to where they’re needed with minimal delay and movement. ONO Lean Logistics focuses on intuitive, operator-centered logistics, ensuring that materials are efficiently sorted, stored, and made instantly accessible—greatly reducing time spent searching or waiting.

The Value of KanbanBOX and ONO Lean Logistics Integration

Integrating KanbanBOX and ONO Lean Logistics addresses the combined needs of inventory management and optimized material handling, creating a seamless flow that aligns with lean manufacturing goals. Through this partnership, companies benefit from a system that not only tracks and manages inventory effectively but also brings it directly to the point of need. This dual approach significantly reduces the need for manual handling, freeing up operators to focus on high-value tasks and eliminating unnecessary movement of materials and people.

The integration is based on robust, modern data exchange systems, making it straightforward and efficient to connect the two platforms. KanbanBOX’s data-driven inventory management pairs seamlessly with ONO Lean Logistics’s hands-on logistics, delivering a powerful solution that maximizes productivity and minimizes waste across the supply chain.

Key Benefits of KanbanBOX and ONO Lean Logistics integration

- Higher efficiency: the integrated solution enables a seamless material flow, ensuring materials are available exactly when and where they are needed. This minimizes delays and optimizes production, as materials are automatically moved closer to assembly lines and workstations.

- Scalability and flexibility: ONO Lean Logistics offers a modular setup that companies can expand over time. This flexibility allows manufacturers to start small and scale up, adding modules as production grows or as specific needs arise. The system’s adaptability supports Lean principles, enabling incremental improvements without the need for large, upfront investments.

- Lean-driven waste reduction: by eliminating excessive stock, minimizing movement, and ensuring that materials are always within reach, the integrated KanbanBOX and ONO Lean Logistics system tackles multiple forms of waste—such as overproduction, waiting times, and excessive handling. The result is a leaner, more focused production environment where operators can dedicate their efforts to value-adding activities.

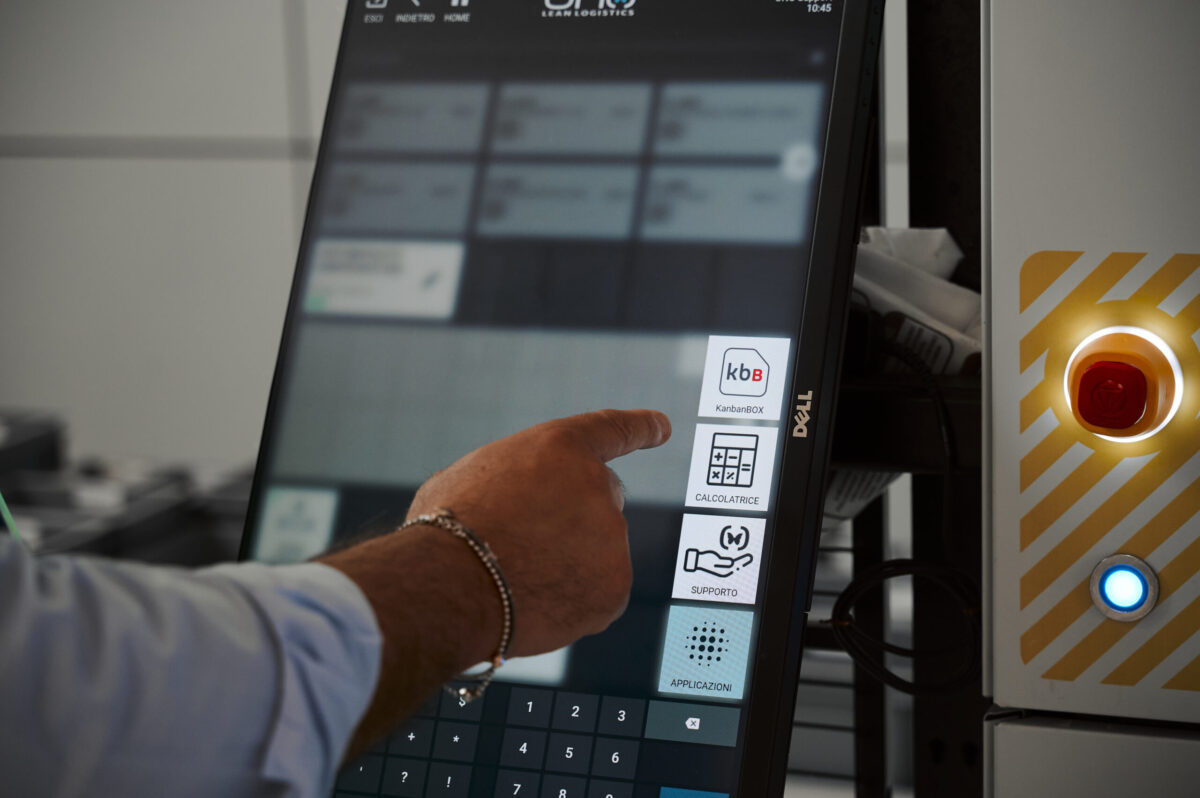

- User-friendly implementation and fast adoption: KanbanBOX and ONO Lean Logistics prioritize ease of use, allowing operators to quickly adopt the system with minimal training. The intuitive interfaces make it easy for employees to monitor stock levels, retrieve materials, and adjust inventory flows as needed, improving overall efficiency. Furthermore, KanbanBOX’s user-friendliness extends to external suppliers and clients, making it an ideal choice for companies that aim to simplify supply chain management end-to-end.

- Continual improvement and real-time adaptation: the systems are designed to evolve alongside production needs, providing a flexible approach to continuous improvement. The integration also allows companies to monitor stock and logistics data in real time, making it possible to adjust to production peaks, reduce lead times, and optimize on-the-spot.

KanbanBOX and ONO Lean Logistics: partners since 2015

The two companies have been partners since 2015. The key to this powerful collaboration? The challenges they faced together: ONO Lean Logistics found the answers to its needs in KanbanBOX while KanbanBOX has explored new features thanks to ONO Lean Logistics’ demands.

Do you want to discover more? Watch our exclusive interview with Francesco (Founding Partner at KanbanBOX) and Thomas (CEO and Funder ONO Lean Logistics) or contact us directly to learn how your company can benefit from the efficiency, flexibility and productivity this powerful partnership offers.

“ONO Lean Logistics is a flexible and scalable solution, which goes beyond the concept of automatic warehouse and answers to the concept of Kaizen (continuous improvement). You can install a module and expand it later”

Francesco Dall’Oca – Founding Partner of KanbanBOX

“KanbanBOX is a very intuitive platform that helps check the consumption and production of materials according to the best rules. It is possible to extend it to the whole supply chain, making the relationship with the customers and external suppliers easier. It enables the productive force to gain efficiency and it doesn’t create stock inside one’s own company”

Thomas Ambrosi – CEO and Founder ONO Lean Logistics