Scheduling production plan using Heijunka and creation of an ad hoc sequential Pull process

How to solve the case of particularly sophisticated Saeco Professional assemblies

“There is no good morning that does not bring with it the scent of espresso”.

It is kown that, in the world, espresso speaks Italian. Italian coffee machines dominate unchallenged in the segment of traditional bar machines, for the Office and the Ho.Re.Ca. and their manufacturers represent the true excellence of Italian manufacturing.

Saeco stands out among these. It is a company founded in 1981 in Gaggio Montano, on the Bolognese Apennines, today a protagonist in the world business of coffee machines in and out of the home, in the consumer and professional channels. The first in the world to design the “bean-to-cup” automatic system in 1985, Saeco International Group S.p.A. was acquired in July 2009 by the Philips Group. In 2017 the Vending & Professional Division (with the Saeco and Gaggia brands), taking the name SaGa Coffee Spa, entered the Italian holding company and a global giant in the market of vending machines for drinks and snacks, N&W Global Vending, then EVOCA Group.

Involved in the Mecspe Fair in 2016, KanbanBOX is the tool adopted by Saeco for the management of electronic kanbans and scheduling using Heijunka function of the assembly lines of the OCS (Editor’s note Office Coffee Service) range of professional machines, organised in the Bean-to-cup and Capsule models for offices and small-medium entities.

KanbanBOX allows the enchainment of the two assembly lines responsible for the production of about 120 machines per day each and the synchronization of the warehouse with the production line. Five product groups, about 70 machine variants and an average of 400 kanban cards managed per day.

With the help of Fabrizio Borgognoni, Logistic Manager of Saeco Gaggia Professional, we analysed where and how KanbanBOX intervenes in more detail.

A particularly complex process case is that of OCS machines, solved with a series of customisations designed for the finished capacity sequencing of production on the assembly line.

Assembly lines: the Heijunka for production planning

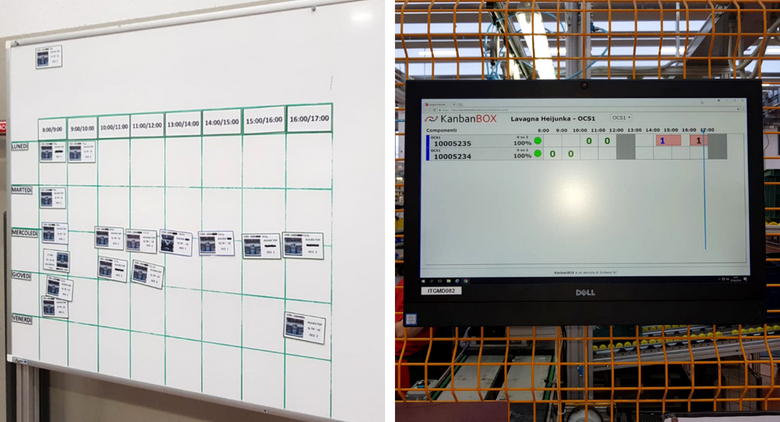

KanbanBOX’s Heijunka module for in-line scheduling of the production plan allows the sequencing of 24-piece pitches attributed to each of the two lines.

KanbanBOX sorts the lots in the correct sequence for the 8-hour shift, indicating the start and end times of production for each, ensuring a real-time display of the progress in the appropriate whiteboard.

Enchainment of the lines: the sequential Pull

Given the many parts to be available in the components supermarket, the enchainment of the materials of the OCS line is designed in sequential Pull mode, with the delivery of the kits of component containers recalled by kanban tags synchronized with each production pitch. This means that the enchainment process by the supplier in charge of preparing the component kits, the Warehouse, takes place only following an order from the downstream process, the Assembly. That is, the delivery of in-line components is pulled by actual production progress.

This is an obligatory choice both for the great variety of components of each batch, so it is not possible to keep all the components in line, also because the procurement process is out of line, with a significant distance from the main flow. An additional benefit of the system is the avoidance of the accumulation of material in line in the event of delays in subsequent production pitches!

Handling Kanban: the multi-process kanban

An additional complication to the enchainment process arose from the long preparation times of the material kits to be delivered online. The kitting phase, with the withdrawal of the components from the supermarket and the repacking in the special boxes equipped with kanban tags, in fact exceeds the 2.45 hours of processing of single batches. On the other hand, the sequential Pull involves a rather fast preparation of material kits.

This is why the kanbans to be moved are prepared one day in advance of production, based on the schedule on the Heijunka whiteboard, in a context of frozen horizon planning.

Through the so-called multi-process kanban, KanbanBOX explodes the kanban cards for each component to be delivered online the next day, organising the setting up of the kits and repacking work of the warehousemen for the day.

Benefits

The benefits of the entire system emerge in the reduction of inefficiencies and production costs, in particular we mention:

- the reduction of stock in the assembly line

- the decisive improvement in the quality of production because the risk of in-line error is eliminated, i.e. the possibility of mounting incorrect components

- the reduction of set-up times, with the possibility of zero minute changes (Zero Quick Changeover/set up)

- the possibility of planning a very wide daily production mix.

Thanks to the digital revolution of a system, the lean one, by nature dedicated to efficiency and continuous improvement, KanbanBOX has allowed Saeco to overcome a manual modus operandi, time-consuming and with a high margin of error, leading the company in a short time to foresee the start of a third assembly line.