KanbanBOX for production plants

The management and control of the production process

Controlling the production cycle is a highly strategic activity for a competitive manufacturing company. For efficient production, capable of facing the instability of demand and quickly satisfying market demands, it is essential not only to plan, but also to balance production by acting on volumes.

KanbanBOX for production, logistics, sequencing and production levelling (Heijunka and Sequencer), allows you to plan production so that it is always in line with customer requests, automate internal logistics and balance the work load inside the production cell. For the supply chain.

The kanban for planning and

levelling production

For a manufacturing company without waste, efficient and capable of quickly satisfying market demands, it is essential not only to plan, but also to balance production.

Given the instability of demand, it is difficult to generate reliable forecasts, while levelling production requires acting on production volumes: KanbanBOX allows you to know the workload and the progress of orders, planning production so that it is always in line with customer demands and allocating inventory to address forecast uncertainty.

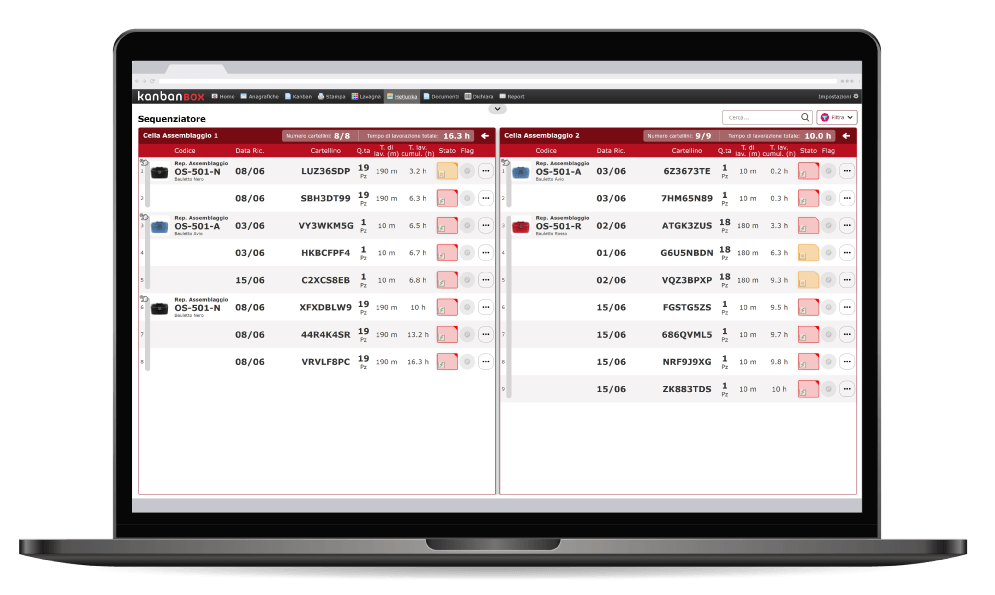

By acting on production levelling (Heijunka), which balances the workload inside the production cell by minimising supply fluctuations, production is aligned with takt time.

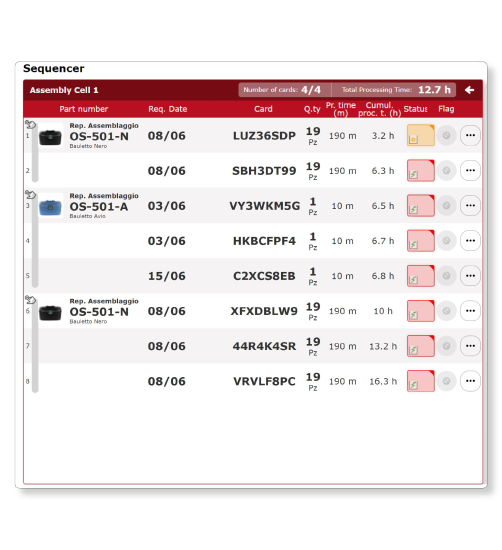

Work plans are optimised by acting on the planning of finished finite capacity production (Sequencer), to establish the best sequences of operations.

The benefits

The following are the benefits:

- processing kanban orders with other production orders

- automatically grouping production batches

- obtaining visibility on workload and progress, monitoring the pace of progression in real time

- avoiding overproduction

- levelling with just one click

- .absorbing demand volatility.

Manufacturing

Size and decrease stock. With KanbanBOX you can manage the production of kanban materials together with other production orders, gaining visibility on workload and order progress. The system also proposes the ideal sizing, reducing stocks without the danger of stock-outs.

Find out moreSequencer

Solve the complexities of manufacturing at finite capacity. The Sequencer is a Lean Manufacturing tool for planning the best sequences of operations on production machines. To make production truly efficient.

Find out moreHeijunka

Level with a click. This function allows the uniform distribution of daily and weekly workloads within the production cells. By displaying the information on the dedicated whiteboard, it adjusts the work rate of the individual operators, levelling picking and monitoring progress in real time.

Find out more