KanbanBOX for the Supply Chain

The solution for a pull-based, connected, and digital supply chain

KanbanBOX is not just an electronic kanban software: it is a comprehensive tool for end-to-end pull material management across the entire supply chain.

From internal production to external suppliers, subcontractors, and final customers, KanbanBOX enables you to build a lean, transparent, and collaborative supply chain, based on real-time data and standardized processes.

Through the digitalization of the kanban system, every flow of materials and information becomes faster, traceable, and integrated, allowing companies to establish clear contractual relationships, automated procedures integrated with their ERP, and shared controls that eliminate inefficiencies typical of traditional processes.

The result is a truly connected supply chain, capable of reacting quickly to demand changes and ensuring continuous material flow according to Lean principles.

Extended Collaboration

Engage suppliers, subcontractors, and customers in a single shared digital environment, where every supply chain partner can monitor all relevant information

Transparency and Visibility

Access real-time data on orders, deliveries, and inventory at any time, ensuring full control of material flow across the entire value chain

Process Automation

Take advantage of automated digital workflows for order transmission, delivery confirmation, and inventory management, reducing time and manual tasks

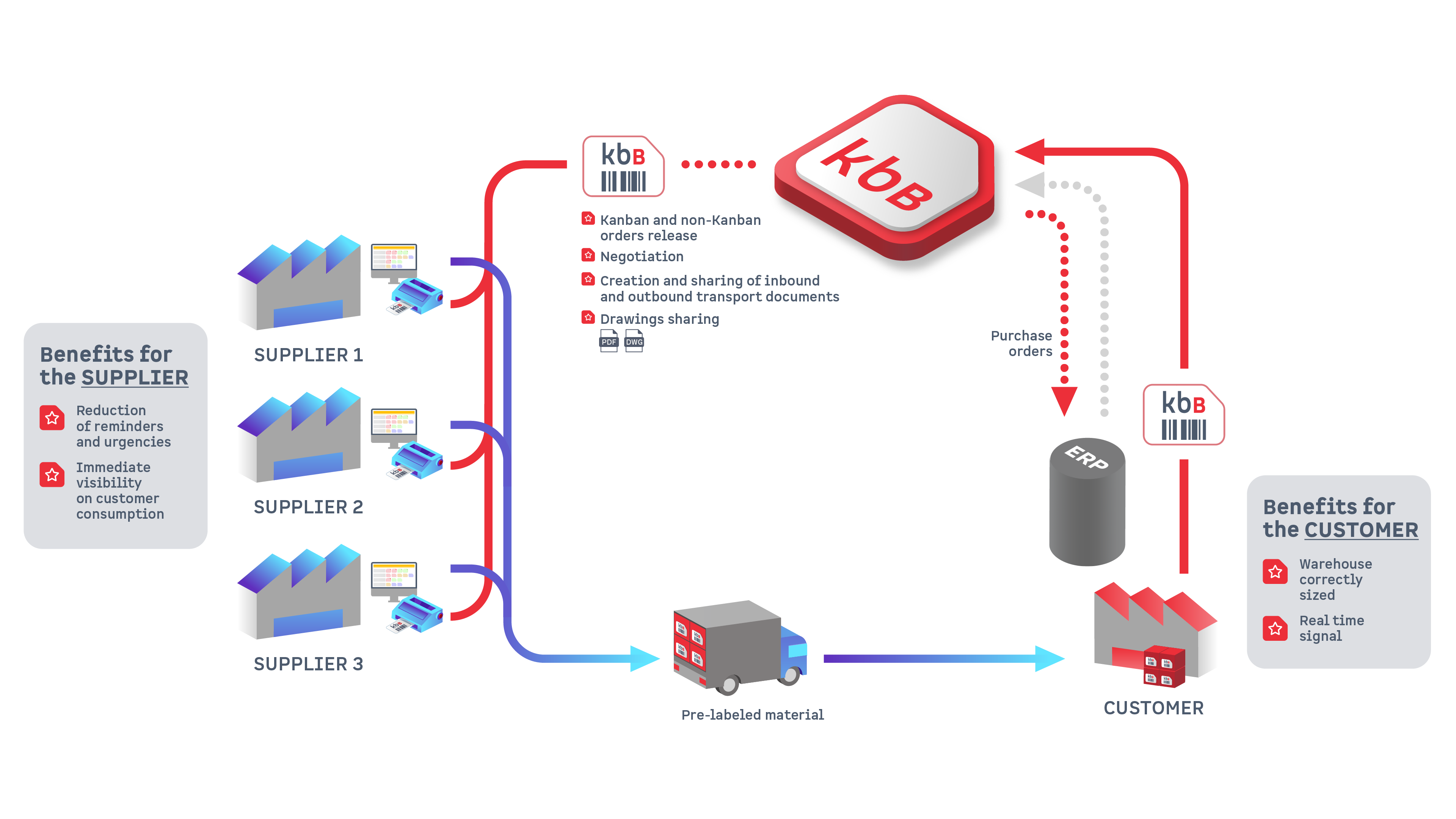

Real-time Connection with Customers and Suppliers

through the shared Digital Board

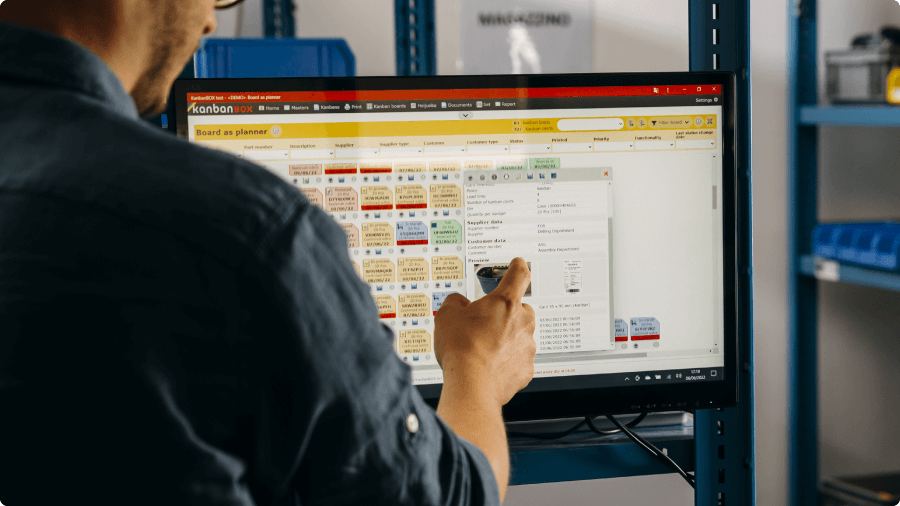

With KanbanBOX, collaboration across the supply chain becomes simple, immediate, and fully digital thanks to the shared board, a tool that connects manufacturers, suppliers, and customers in real time. Here’s what makes it a key element to collaborative flow management:

-

Complete, shared visibility of inventory and orders

The KanbanBOX digital board allows suppliers to see the real-time status of inventory and ongoing orders, clearly and visually.

Each kanban is displayed as available, batching, or to be replenished, with instant updates to keep both sides aligned at all times. -

Instant transmission of orders, data, and updates

When a recurring order container is emptied or a new closed order is entered, the information is transmitted instantly through the platform, ensuring immediate synchronization across the entire supply chain.

Any notes or issues can be added directly as comments on the board, automatically notified to the other party and fully tracked within the platform. -

Standardized process

All parameters (minimum quantities, lot sizes, kanban policy, etc.) are agreed upon from the start.

Communication happens directly on the platform, eliminating emails and calls, and ensuring clarity and operational consistency throughout the process.

-

Easy to adopt and use

As a web-based platform, KanbanBOX requires no installation or setup: suppliers and customers can access it directly from their browser, anywhere.

The intuitive interface ensures a smooth adoption process, even for users without technical skills. -

Unlimited connections

Connect as many suppliers and customers as you want: your subscription doesn’t depend on how many partners you add, but on how much you use the platform (number of kanban loops). And for your suppliers and customers, the license is completely free, making collaboration even easier.

With the KanbanBOX shared board, the supply chain becomes more connected, transparent, and responsive , creating a collaborative ecosystem that grows with your business.

Beyond the Digital Board:

ERP Integration and Document Management

KanbanBOX makes supply chain management smoother and more automated with a suite of advanced features designed to streamline communication, reduce errors, and speed up operations between customers and suppliers:

-

ERP integration

Synchronize procurement processes through direct ERP integration, enabling automatic creation of purchase orders, inventory level updates and much more. -

Integrated document management and automatic label creation

Automate the creation and sharing of shipping documents (DDTs) and generate labels for supplied materials automatically, choosing from available templates within the platform. -

Technical drawing sharing

Give operators real-time access to updated technical drawings, reducing production errors and ensuring alignment across all parties.

With these features, KanbanBOX transforms your supply chain into a connected, transparent, and collaborative digital ecosystem, where every piece of information is available at the right time and place.

Beyond kanban: manage closed orders

KanbanBOX isn’t limited to kanban-based workflows: it also allows you to manage closed orders, integrating all procurement flows into a single system.

This lets you coordinate materials managed under different logics while maintaining full traceability, visibility, and control over every order.

From theory to practice: the Robopac example

Among the companies that have digitalized their supply chain with KanbanBOX there is Robopac, a world leader in packaging technologies.

By implementing KanbanBOX, Robopac made its procurement processes leaner, more traceable, and collaborative, improving communication between suppliers and production departments.

KanbanBOX for sales and distribution

KanbanBOX goes beyond production: it can also be used in sales and distribution processes, managing the pull flow of materials toward customers and distributors.

With real-time traceability and a shared digital board, suppliers can monitor customer inventory, plan replenishment automatically, and ensure on-time deliveries, boosting efficiency across the entire distribution chain.

Do you have any questions?

References

Case studies

Robopac | Packaging machines

With KanbanBOX, Robopac achieved a more integrated, responsive, and digitalized supply chain thanks to the integration with both external suppliers and SAP

BCS | Agricultural Mechanization

BCS moved from push to pull through E-kanban for suppliers, production, and internal flows. They now manage 6000 kanban loops across 3 plants and integrated KanbanBOX with SAP

El.Co. | Industrial Electrical Automation

El.Co. has simplified the maintenance of kanbans with e-kanban, which was previously so onerous that the number of parts managed by kanban had to be limited

Orotig | Welding Industry

Orotig has implemented sequential pull in the company, optimizing multi-process production scheduling and supplier integration with KanbanBOX

Rossi SpA | Gearmotors and Electric Motors

Rossi Spa has digitalized the existing production and move kanban, and then integrated it with its own ERP, with the Oracle Sequencer and with the suppliers

Aptiv | High-tech automotive systems

From the introduction of kanban to the transition to e-kanban. The Lean Improvement journey of the largest manufacturer of electronic interconnection systems for the automotive sector