KanbanBOX and digital innovation for a Smart Factory

We support large, medium and small companies in the process of digitalisation of orders

KanbanBOX improves organisational processes, products and services thanks to the most innovative technologies and digital methodologies.

With over 3,000 references in Italy and abroad, KanbanBOX is the most complete tool offered to company teams to carry out automated reordering, through a fast and accessible in-Cloud web platform, capable of enhancing the entire value chain.

Large companies and SMEs are called upon to innovate their businesses in order to resist an increasingly rapid and fluid market: the digital evolution of the lean technique proposed by KanbanBOX guides, through the application of an electronic kanban management system of the flow of materials, a process of change that is first of all cultural, concerns business transformation and connected to technology.

The opportunities of Industry 4.0

Industry 4.0 is the manufacturing model of the future. Thanks to Smart Technologies, companies will be increasingly connected and able to increase cooperation between their resources, involving people, goods, knowledge and information. A virtuous model that operates internally and extends to the entire Value chain, improving production and increasing efficiency and competitiveness.

Innovation is a great opportunity for companies, especially for the manufacturing sector. There are numerous measures to choose from to overcome not only the challenges of the markets, but also and above all those of digitization. To create a competitive industry, to accelerate innovation and address the markets, to be among the protagonists of the development of Smart Manufacturing, to be ready for the future and not to miss out on Industry 4.0.

Automate processes

with an Industry 4.0 approach

Taking up the challenges of the digital revolution that is underway and Industry 4.0, KanbanBOX is equipped with tools and solutions that combine the smart technology of an electronic kanban (e-kanban) with systems to fully automate the flow of materials.

Thanks to the interconnection of machinery allowed by the IoT, KanbanBOX is able to communicate with the work centres and the various company production resources according to 4.0 logic. The result: higher productivity and higher efficiency.

KanbanBOX natively allows the communication and transmission of information between central and peripheral decision makers, achieved through specific modules such as the Sequencer.

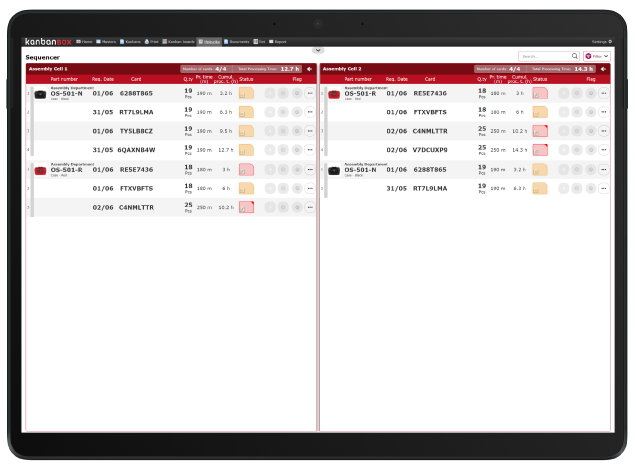

Sequencer

The Sequencer is a function aimed at simplifying the work of operators thanks to the integrated connectivity and remote monitoring of machines which automatically reads and executes work orders. Collect data in real time and monitor events on each individual machine or all your machines, configuring notifications and permissions.

Thanks to the Sequencer, you can manage the complexities of professional sheet metal processing, taking full advantage of laser cutting machines, punching machines or laser bending machines for the production of sets of components that belong to multiple work orders. The intuitive and easy-to-use planning interface and the integrated connectivity function simplify even the most complex machining tasks. Saving material, costs and effort.