Electronic Kanban vs Traditional Kanban: the Benefits

By Francesco Dall'Oca

In this article, we’ll go over the kanban system characteristics, the benefits it offers and the limitations of using the traditional one, namely the manual kanban. The good news is that today there are also electronic kanban, with far more more features.

Kanban: manual or electronic

Manual kanban is a lean manufacturing tactic for managing material replenishment flows, using a visual board. Through the use of kanban cards that are hung on it, it shows which material you have to restore.

The cards travel along with the product they represent. The product is often contained, even in multiple pieces, in a box and the card is hung on that box.

The kanban system can be applied in various business areas. It is useful for purchases made from external suppliers (purchase kanban), for managing products sold to customers (sales kanban), for the logistics department (move kanban) and, of course, for production (production kanban).

Therefore, when a card goes from the product to the board, it can indicate that such material is

- to be produced, in order to sell it;

- to be purchased, because it is about to run out;

- to be moved, for example to bring it closer to the production or assembly lines.

In a kanban system, physicality is the strong point, because moving the cards and seeing them populate the kanban board allows you to always keep track of stock and avoid stock breaks. In addition, in the long run this method makes it possible to level out stocks and production, ensuring a constant pace and limiting production peaks.

Another very important lean aspect of this system is that the operators are directly responsible for moving the cards. The task of reporting what to restore or what to produce is in their hands and no longer exclusively in the hands of offices and managers. This increases everyone’s engagement, as well as enhancing the autonomy of the company’s employees.

Indeed, the kanban method is a real philosophy. An approach that is not limited to the use of a tool, but also affects and transforms the human aspect of the company.

So why choose to buy e-kanban software if you can have all these benefits with a board and a handful of cards?

Manual Kanban Limits

Despite the many advantages just discussed, manual kanban has some issues that arise when extending the system.

Let’s assume, for example, that you want to use kanban with external suppliers, or with another plant. This is impossible unless you combine another communication channel with it, such as e-mail. In this way, however, the inherent advantage of kanban will be lost.

Another unsustainable scenario occurs as the number of codes to manage increases, because that means new boards, more paper cards to print, move… and not to lose.

The more complexity grows in the company, the more difficult it is for the manual method to sustain itself, due to issues related to

- communication

- maintenance

- data management

When a new factor arrives the switch to electronic kanban is mandatory.

What is electronic kanban software

The electronic kanban software is a software that follows the logic of the manual kanban, facilitating the replenishment of material by enhancing them through the electronic management of information and restore signals.

Advantages of E-kanban

An e-kanban software brings with it all the advantages of manual kanban, increasing them, precisely because a software can process much more information than any human.

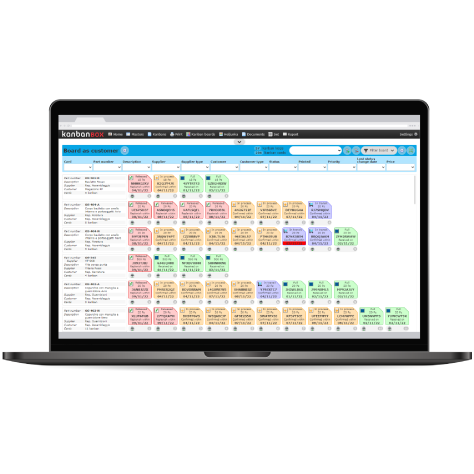

In an e-kanban software, the kanban cards are both printed and digitized. This means that each paper card, applied to the box, is matched by a digital one. It is the latter that is “managed in the digital kanban board.” This way, you avoid the displacement of the physical card, which can be thrown away as soon as the corresponding material has been used. By scanning the barcode of the card, its digital alter ego will update.

On some e-kanban software, such as KanbanBOX, the board can be shared with all suppliers for free. In this way, information is shared in real time. This eliminates the need to send orders through other software, e-mail, or phone calls.

Moreover, the software suggests how to size the kanban (add or remove components from the box) as needed. It can do this because it constantly analyzes consumption trends. This analysis also makes it possible to obtain dashboards with KPIs and metrics to evaluate your own consumption, your relationship with suppliers, and start from there to adjust your strategy.

Electronic kanban is valuable in situations of high complexity. However, it can also be successfully implemented in smaller companies, or those with few codes to manage. A gradual adoption is often recommended anyway, to allow your team to become familiar with the tool.

Where to Use the Kanban Software

If you were wondering where the kanban framework comes from, it originated in Toyota and has spread more to manufacturing companies. However, it can be applied in any field. The key thing is that you need to manage components whose frequency of consumption is high.

For example, a kanban system would also be usable to manage personal shopping! It would show us what to buy at the supermarket, without the risk of taking too much because we were convinced by the discount or forgetting something because we were in a hurry.

Choosing to use software is a natural step as volumes increase as we saw in the previous paragraphs. Perhaps for grocery shopping we will never really need it, but in a company that works with external suppliers it becomes a must.

E-kanban in the Healthcare industry

One area where the electronic kanban system is still uncommon but where there is much potential is the health care sector. We got this feedback by collaborating with the Oscar Lambret Center, which has implemented KanbanBOX to optimize the replenishment of emergency drugs and medical devices from the central internal warehouse to the various wards.

KanbanBOX: an example of e-kanban software

Kanban software usually exists as modules of a larger software, the ERP. The advantage companies see is that they have a single vendor offering software with multiple purposes, including managing the restocking of materials.

On the other hand, it is possible that there is no real specialization in electronic kanban software and that it is treated as yet another module in an overall package.

KanbanBOX is a kanban software that has instead been developed from long experience in lean consulting. We analyze customer use cases daily to offer a product that meets the real needs of companies.

The only one on the market to offer free licenses for suppliers, it stands out for its ease of use and quick implementation (on average, four days). To see the features in action, you can find videos on our YouTube channel.

KanbanBOX is a software that offers standard modules, which can be activated depending on the business need. Our lean and technical consultants are available to discuss together your use case and how e-kanban can be implemented to bring you maximum benefits.

Do you want a deeper comparison between Eletronic Kanban and Manual Kanban?

Download the Guide