How to fix the vulnerability of the supply chain

By Guido Bonuzzi

The tools to produce on the basis of real needs

When talking about the Vulnerability of the supply chain, the objective can be summed up in three key words: predict, stabilize and level.

More and more companies are looking for solutions to absorb the extreme volatility and unpredictability of the markets, which generate vulnerability of the supply chain capable of putting both small and large organizations in serious difficulty. But fortunately there are two tools that allow you to effectively address the issue: the Heijunka and the Sequencer.

In particular, the growing interest in Heijunka, in a sector linked to the production of material goods such as manufacturing, is due to its ability to transform the unpredictability of the market into predictable work planning. But if the outcome is to balance the workload to satisfy an irregular demand, it is not always said that the input may be the same…

The vulnerability of the supply chain: solutions

The misalignment between demand and production translates, for companies, into a continuous succession of production peaks alternating with periods of a slowdown in which requests decrease. In addition to moments of intense production stress, the consequences are the accumulation of stocks, i.e. finished products that remain unsold; machine downtime; sudden changes in deliveries and supplies; waste of raw materials, and time… In short, inefficiencies and waste witch generate high costs.

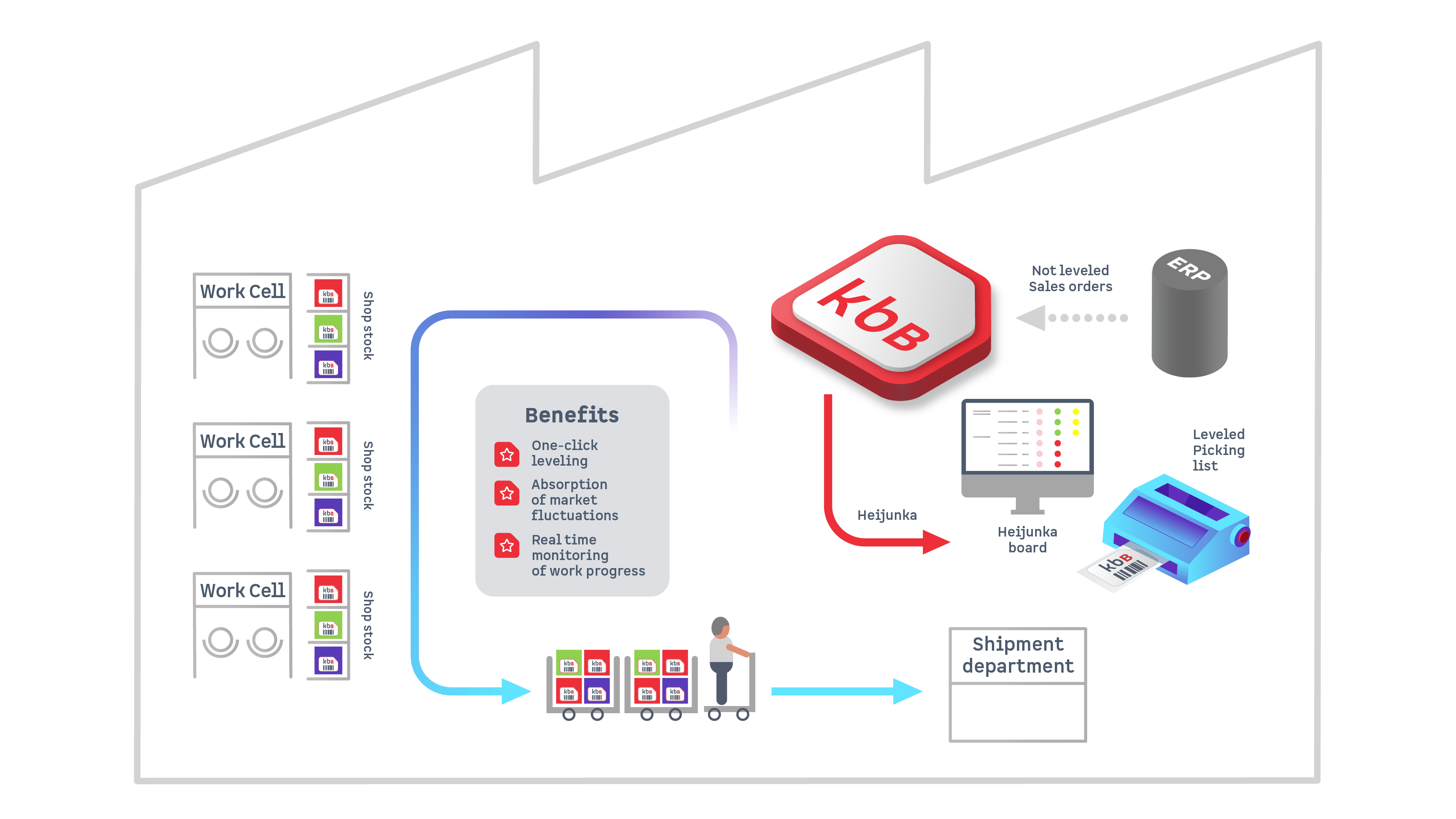

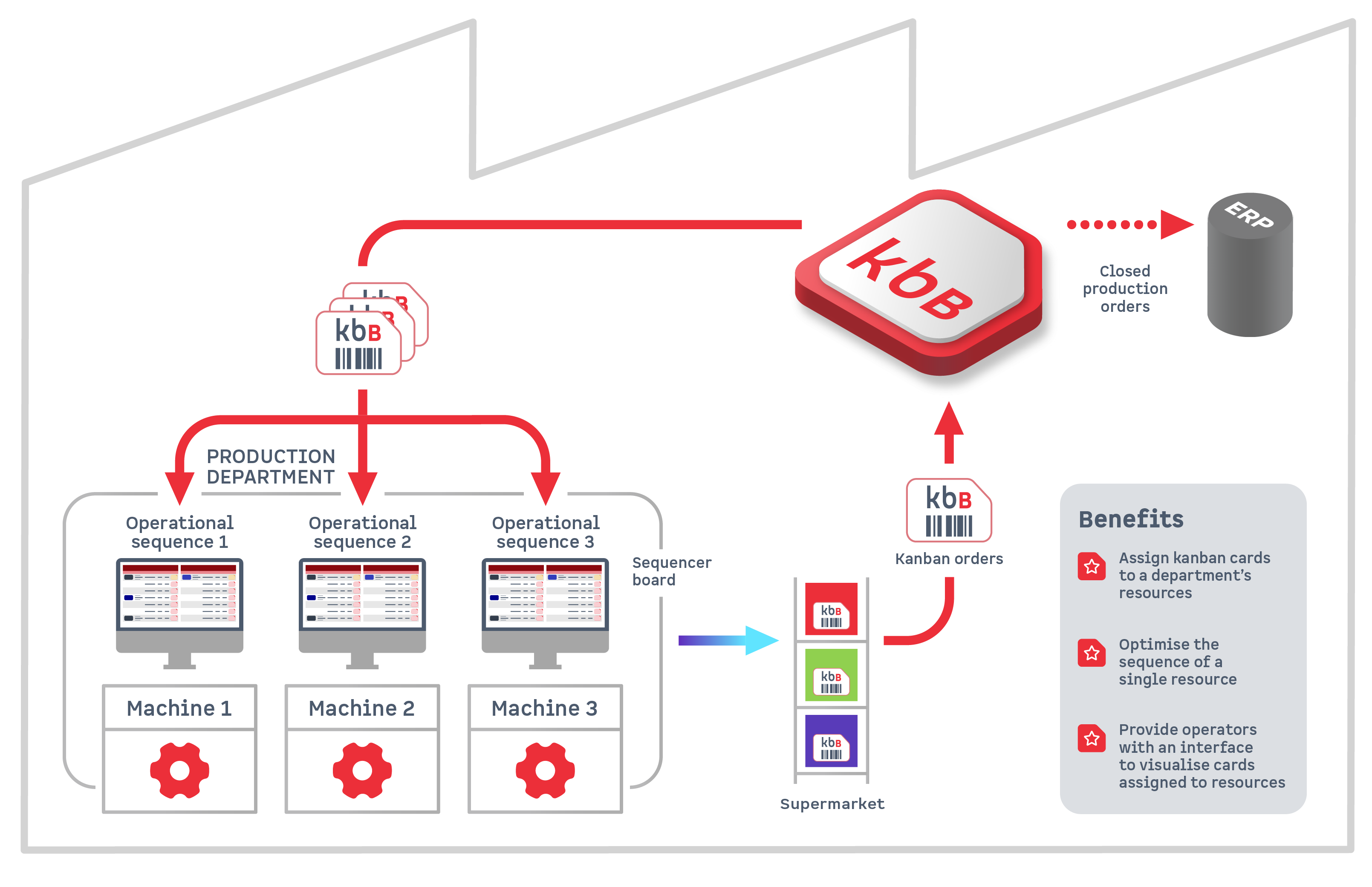

KanbanBOX solves the problem of the unsteady production trend through two different levelling tools that you have undoubtedly already heard of: the Heijunka and the Sequencer.

Between theory, practice, and a lot of experience in the field

What is Heijunka for?

Heijunka is a Lean Manufacturing technique used to implement Just In Time. It is a very rigorous and rigid system: the conditions for its applicability are the presence of production with low product variability. Its levelling principle is based on the temporal planning of production according to a constant rate calculated in advance on average values which aims to manufacture the same mix of products, in the exact quantities, every day.

This proceeding at a constant “cruising speed” makes it possible to minimize fluctuations in demand within the supply chain, optimize resources based on the production volume, reduce the stock of finished products, and, consequently, the generated costs.

What is Sequencer for?

However, not all companies can produce the same quantities of products every day, because they have multiple series and multiple product types, sometimes all with different manufacturing processes and assembly times. That’s why to solve the problem of production control in the presence of process variability and resources that are not always available (such as machines shared between several departments) we created the Sequencer.

What is its function? The Sequencer automatically assigns the cards to be produced to the various resources by monitoring the workload in real-time, allowing the head of the department to intervene to redistribute it if necessary. In short, a fundamental tool to distribute the workload and have visibility over the entire production.

Any question? Contact us!

The Heijunka

Stabilizes the pace of production by balancing the workload within the production cells.

Benefits:

- Uniform distribution of manpower, materials, and movements

- Leveling of volume and production mix

- Elimination of consumption peaks and production accumulations.

The Sequencer

Distributes the workload among the machines by sequencing the correct production order.

Benefits:

- Easier distribution of the workload between the machines

- Production leveling even with process variability and resources not always available

- Visibility on all production.