Make to Order

Plan, increase efficiency, deliver on time and reduce production costs. Optimise your production with a unique tool!

In a Make to order (MTO) production model, production is pulled from the customer’s order (Pull System). A strategy opposite to Make to Stock (MTS) is where production is instead based on forecasts of future demand based on past data. A system with a high probability of forecast error and capable of generating too many stocks, subject to waste and obsolescence – and too low liquidity.

Achieve maximum production efficiency

KanbanBOX is the right solution for:

- quickly reaching the highest production efficiency

- better meeting the demand and needs of your customers

- planning resources and materials to optimise production performance

- increasing your competitiveness on the market.

Build an advanced production process

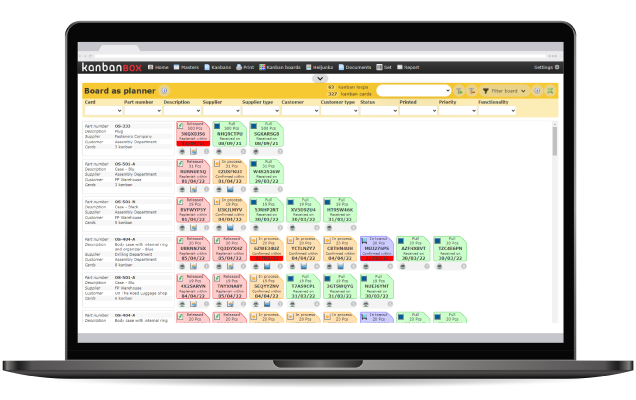

With KanbanBOX you can:

- manage the entire production process from a Lean Manufacturing perspective

- obtain complete visibility on departments, resources and materials thanks to real-time data updates and integration with the ERP and all other company information systems

- create production plans according to a Pull model, optimising activities for individual resources or cells

- create a digital and collaborative supply chain.

Case studies

BCS | Agricultural Mechanization

BCS moved from push to pull through E-kanban for suppliers, production, and internal flows. They now manage 6000 kanban loops across 3 plants and integrated KanbanBOX with SAP

El.Co. | Industrial Electrical Automation

El.Co. has simplified the maintenance of kanbans with e-kanban, which was previously so onerous that the number of parts managed by kanban had to be limited

Orotig | Welding Industry

Orotig has implemented sequential pull in the company, optimizing multi-process production scheduling and supplier integration with KanbanBOX

Rossi SpA | Gearmotors and Electric Motors

Rossi Spa has digitalized the existing production and move kanban, and then integrated it with its own ERP, with the Oracle Sequencer and with the suppliers

Aptiv | High-tech automotive systems

From the introduction of kanban to the transition to e-kanban. The Lean Improvement journey of the largest manufacturer of electronic interconnection systems for the automotive sector

References