Production Scheduling with the Sequencer

The Lean KanbanBOX Feature That Keeps Production Flowing

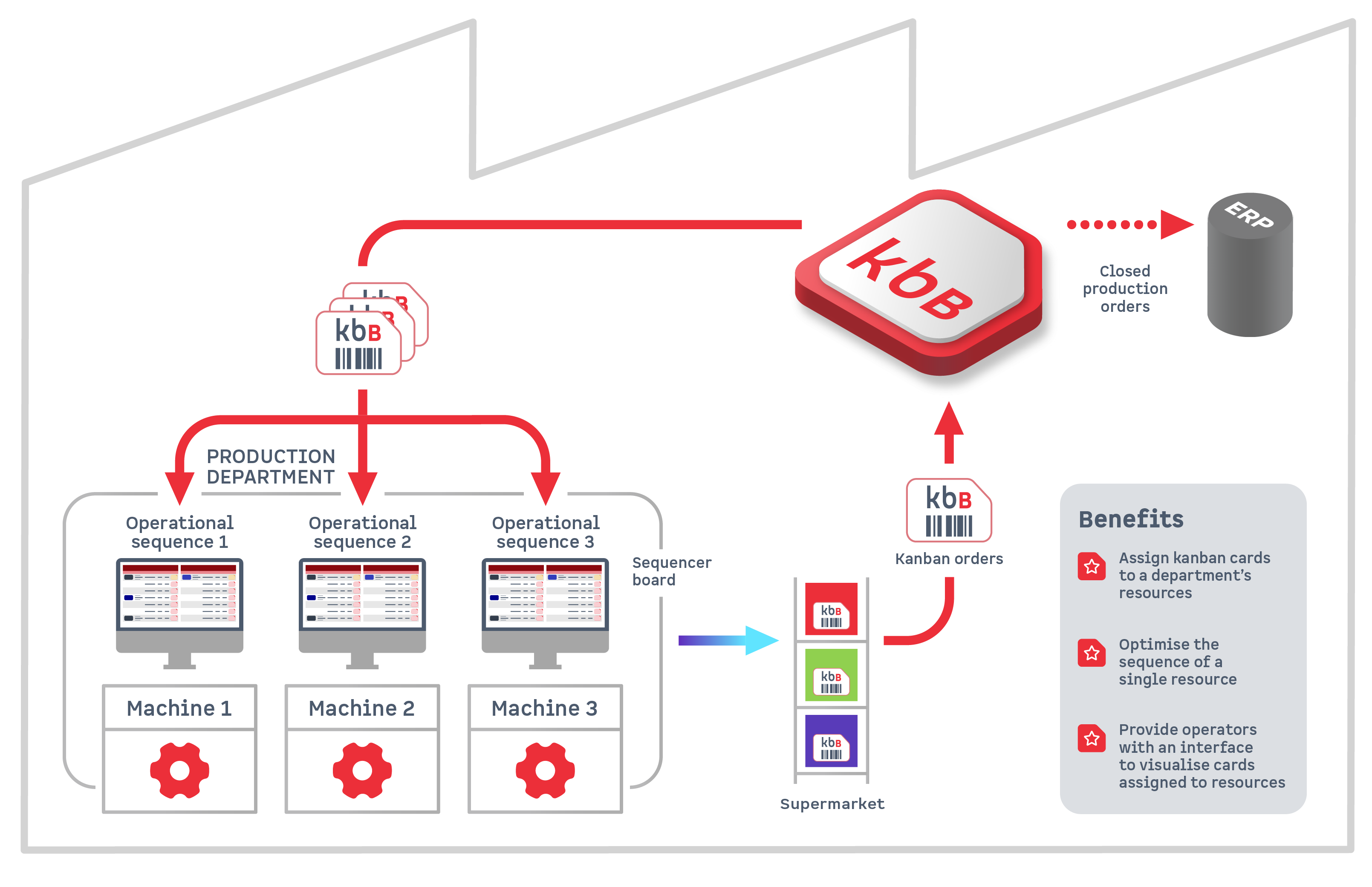

The Sequencer is a Lean Manufacturing tool designed to schedule the optimal sequence of operations across production machines. It is one of KanbanBOX’s advanced features for efficient, real-time production planning.

With the Sequencer, you can:

-

Distribute workloads efficiently across available resources and schedule production at finite capacity

-

Plan the daily production flow to ensure the right quantities are produced in the right order

-

Simplify the complex daily task of scheduling, typically handled by the production manager or team lead

The Sequencer: Plan, Distribute, Organize

Regulate

Do you manage unstable production caused by process variability or inconsistent resource availability? The Sequencer gives you the tools you need to maintain flow and balance.

Distribute

Is your team leader struggling to see the full picture? With the Sequencer, you can clearly distribute workloads across machines and gain full visibility into production status.

Organize

Unsure which materials to prioritize? The Sequencer automatically suggests the correct production order. And if needed, you can manually adjust the sequence with a single click.

A Practical Support for the Work Plan

Starting from the planner’s proposed schedule, the Sequencer helps define the best operation sequence for each machine, creating well-organized programs and communicating work plans, and any updates, clearly to the shop floor.

-

Assign kanban cards to specific production resources

-

Optimize the work sequence for each machine or station

-

Provide operators with a dedicated interface to view assigned tasks

It’s a practical tool that improves real-time scheduling directly on the line, making your production more efficient and less prone to interruption.

The KanbanBOX Sequencer Board

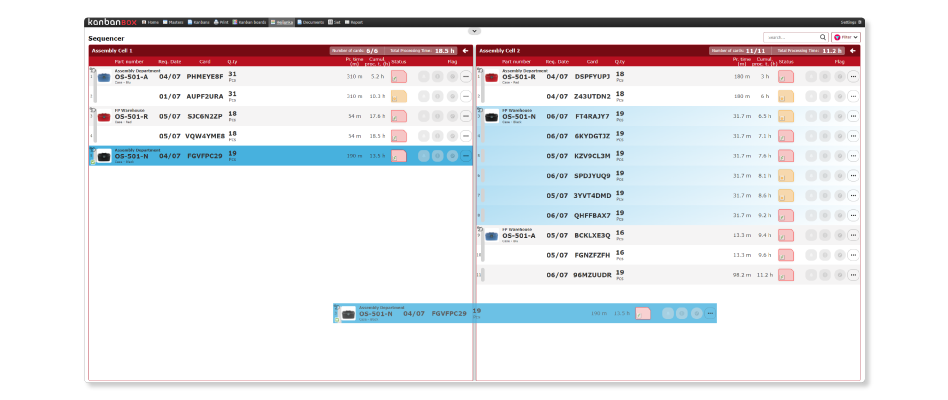

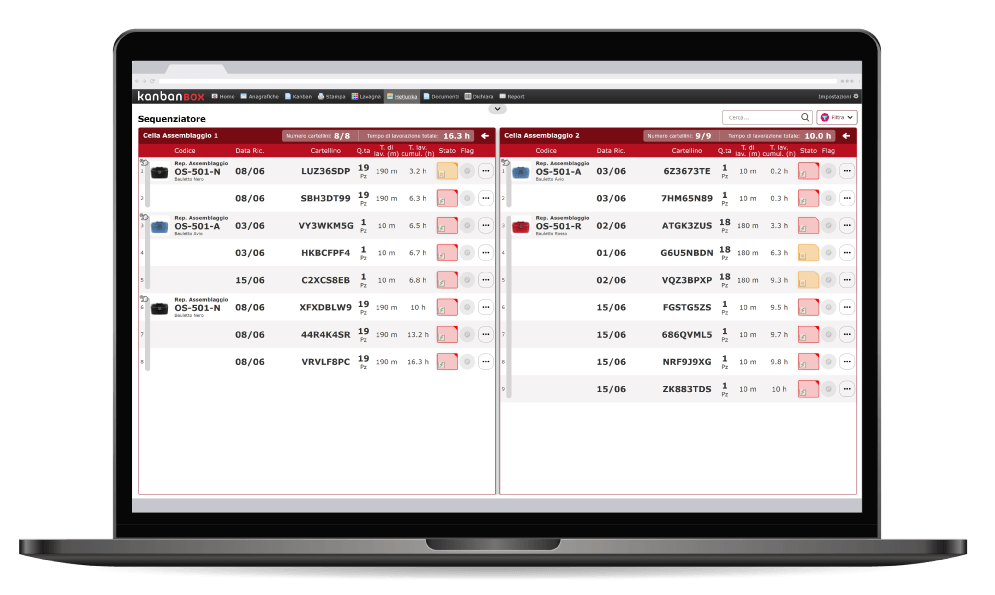

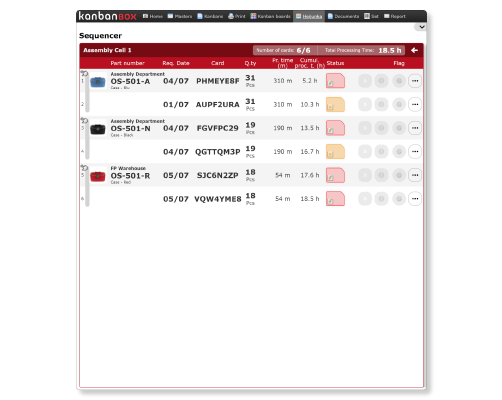

The Sequencer interface in KanbanBOX is:

-

Simple and intuitive: move cards easily between resource sequences with just one click

-

Easily configurable: use drag-and-drop to arrange your schedule directly

-

Accessible from any device: whether it’s a tablet, smartphone, or PC, you can access the board via web browser or the KanbanBOX app

How the Sequencer works

At the organizational level, the Sequencer allows you to build a list of production tasks quickly and effectively by:

-

Defining the resources involved (e.g., machines linked to kanban cards)

-

Grouping resources into departments (e.g., turning or milling stations)

-

Assigning default resources to each kanban relationship

Watch the Sequencer in Action

Thanks to the KanbanBOX Sequencer, it’s easy to optimize production planning in a simple and intuitive way. Watch the demo video and see how easy it is to use the Sequencer in real-world conditions.

Watch the videoOther top functionalities: Heijunka

Discover Heijunka, one of KanbanBOX’s core features for leveling production. It helps you maintain a constant production rhythm and balance workloads across lines or within individual cells.

Read moreReferences

Case studies

Sacchi | Electrical Supply Distribution

Sacchi uses KanbanBOX to offer its customers a kanban-based sales service, ideal for recurring supplies and supports long-term customer loyalty

Robopac | Packaging machines

With KanbanBOX, Robopac achieved a more integrated, responsive, and digitalized supply chain thanks to the integration with both external suppliers and SAP

BCS | Agricultural Mechanization

BCS moved from push to pull through E-kanban for suppliers, production, and internal flows. They now manage 6000 kanban loops across 3 plants

El.Co. | Industrial Electrical Automation

El.Co. has simplified the maintenance of kanbans with e-kanban, which was previously so onerous that the number of parts managed by kanban had to be limited

Orotig | Welding Industry

Orotig has implemented sequential pull in the company, optimizing multi-process production scheduling and supplier integration with KanbanBOX

Rossi SpA | Gearmotors and Electric Motors

Rossi Spa has digitalized the existing production and move kanban, then integrated it with its own ERP, with Oracle Sequencer and with suppliers

Aptiv | High-tech automotive systems

From the introduction of kanban to the transition to e-kanban. The Lean Improvement journey of the largest manufacturer of electronic interconnection systems for the automotive sector