What is Electronic Kanban

By Matteo Biagini

Electronic Kanban (also known as e-kanban) is the modern evolution of the traditional kanban system. It’s implemented via the adoption of an electronic kanban software which enhances the physical system with the advantages of digitalization.

Once implemented, electronic kanban allows the company to:

- Automate and enhance kanban process, improving communication, accuracy and efficiency

- Overcome traditional kanban’s limits (e.g. complexity in managing multi-process)

- Expand the benefits of kanban to the whole supply chain, including suppliers and costumers

Let’s discover more about what is electronic kanban.

What is a traditional kanban system

The best way to answer question “what is electronic kanban” is to start with the definition of traditional kanban.

Traditional kanban, also called Manual Kanban or simply Kanban, is a powerful tool to manage material replenishment. It employs physical cards (called kanban cards) attached on the containers of the materials managed by the company (raw materials, semi-finished products, components…). When a container it’s emptied, the operator detaches the kanban card from the container and delivers the card to the internal supplier as signal of the needed replenishment. You can find a more detailed description of this process in this article: https://www.kanbanbox.com/kanban-inventory-management-what-it-is-how-works/.

Kanban systems are highly adaptable, with applications spanning various business areas:

- Purchase kanban: coordinating restocking from external suppliers

- Sales kanban: managing inventory for customer orders

- Move kanban: overseeing internal logistics and stock transfers

- Production kanban: synchronizing manufacturing activities with demand.

Over time, this approach balances stock levels, stabilizes production flows, and minimizes waste.

Why companies move from traditional kanban to electronic kanban

Despite its many advantages, traditional kanban has limitations, particularly in scaling beyond small or localized operations. Key issues include:

- Communication barriers: extending traditional kanban to external suppliers or other facilities requires supplementary channels like email, undermining the system’s inherent simplicity.

- Scalability issues: managing a growing number of stock codes necessitates additional resources like time, space and effort, increasing the risk of human errors and inefficiencies.

- Data management limitations: manual systems cannot easily track or analyze stock levels, replenishment trends, or performance metrics, which are critical for decision-making in modern supply chains.

As businesses grow or integrate with complex supply networks, these challenges make traditional kanban increasingly unsustainable.

What is electronic kanban? The evolution of traditional kanban

Electronic kanban doesn’t substitute traditional kanban, it enhances it. This means materials managed with an electronic kanban software are still organized in standardize containers with a kanban card applied to them. But:

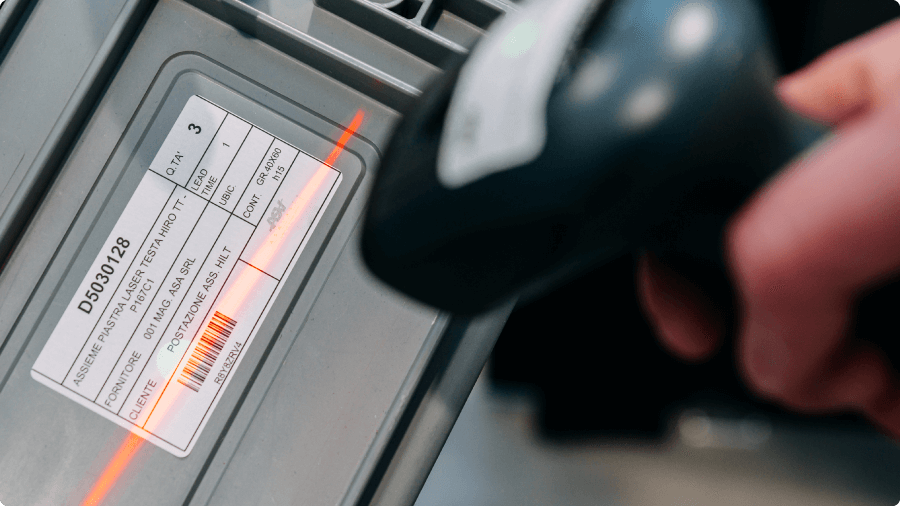

- The card applied on each inventory container is enriched with a unique barcode

- Operators are equipped with a device able to scan the barcode

- Suppliers and production lines are provided with screens with browser connection from which they can access the electronic kanban software.

Once these few preparatory steps have been implemented, the electronic kanban system is ready to go: when operators empties an inventory container, they scan the barcode applied on the container. This scan sends a real-time replenishment signal to the digital screen of the supplier (internal or external), ensuring seamless communication and minimizing manual errors.

Upgrades from traditional to electronic kanban

Unlike traditional kanban, which works best within a single facility or small-scale operation, electronic kanban seamlessly integrates across multiple locations and stakeholders, including suppliers, production teams, and distribution networks.

By converting physical signals into digital data, it automates and enhances kanban processes. It also enables instantaneous communication, reduces the risk of human error, and ensures replenishment occurs exactly when needed.

It also gives full visibility on replenishment processes and inventory management, synchronizing it with actual consumption patterns. It also empowers businesses with real-time insights into inventory levels and supply chain performance.

Moreover, electronic kanban supports scalability, making it an ideal solution for businesses looking to grow and adopt new technologies. It’s integrable with companies ERP (Enterprise Resources Planning), WMS (Warehouse Management System), AGV (Automated Guided Vehicles), RFID System (technology uses radio waves to identify people or objects and their movements) and Power BI for data analysis.

Why to switch to electronic kanban

Switching to electronic kanban is particularly beneficial for companies handling large-scale operations or complex supply chains.

For businesses looking to improve their replenishment management flow, electronic kanban represents a significant leap forward, combining the simplicity of traditional kanban with the power of digital technology.

Now that you know the answer to “What is electronic kanban”, discover more about its advantages in this article: www.kanbanbox.com/electronic-kanban-advantages/.

Download the Electronic Kanban Guide

Do you want to learn more about the topic? Download our Electronic Kanban Guide with clear and concise explanations, diagrams and processes explained step by step.

To download the Guide which explains what it is, how it works and what are the advantages of Electronic Kanban compared to Traditional Kanban, visit this page or fill out the form below!