What is kanban: definition, meaning and 5 use cases

By Matteo Biagini

Clarifying what is Kanban: Card, Method, Board

“What is kanban?” is the most searched question by individuals exploring production and organizational management. However, online searches often yield partial or conflicting definitions, leading to confusion. This article aims to provide a clear and concise answer to the question “what is kanban?” and its various applications.

|

|

Etymology and General Definition

The term kanban (accent on the first A, pronounced kànban) is a Japanese word that translates to “signal” or “visual card” since derives from the union of Kan (visual, 看) and Ban (signal, 板). Generally, kanban helps optimize work using visual signals, with its form varying based on the context.

|

|

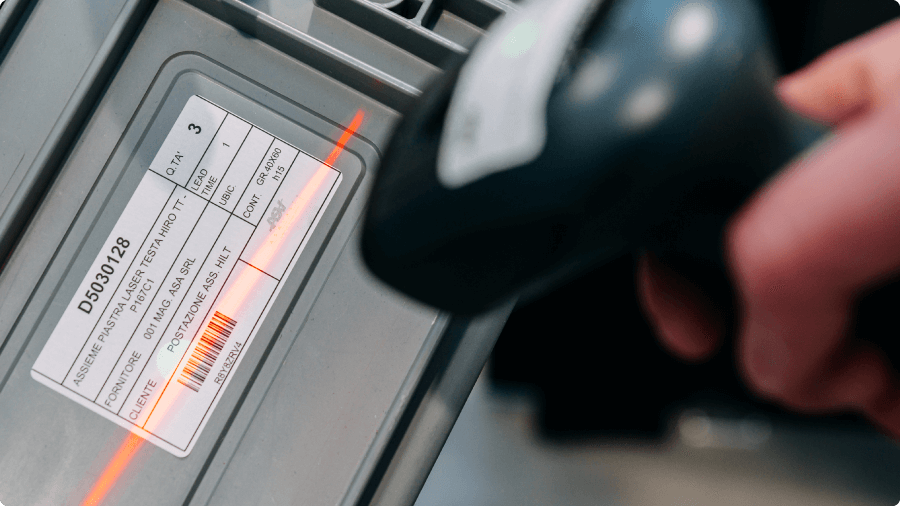

What is Kanban as a Card (Kanban Card)

In its simplest form, particularly in the production sector, a kanban is a paper card featuring:

- Placement on the outside of a container, either permanently (e.g., adhesive paper) or temporarily (e.g., by insertion).

- Summary information about the container’s content, such as item name and code, quantity, supplier, etc.

- Facilitation of activities foreseen for that component e.g. move kanban, purchase kanban, production kanban.

For instance, let’s think about an operator at a workstation installing handles. When the handles container is empty, the operator sends the kanban card attached to it to the warehouse: the storekeeper will replenish the handles based on the kanban card’s information, ensuring efficient restocking without the need of a third-party approval.

|

|

Kanban can also refer to other objects in the production field that visually signal requested actions:

- Empty containers (with no kanban card) indicating a need for material replenishment.

- Empty spaces signaling the necessity to fill them with required components.

|

|

E-kanban o cartellino elettronico

An electronic kanban (also known as e-kanban) is a kanban card which presents also barcodes, QR codes, or RFID chips to transmit some information electronically.

This allows an operator to communicate the need for replenishment by simply scanning a barcode, eliminating the need to physically hand over the card. For discovering more on e-kanban’s features and benefits compared to traditional kanban, refer to this article.

|

|

What is Kanban as a Production Management System (Kanban System or Method)

Kanban cards are fundamental to the kanban system or method, a production management strategy developed by Taiichi Ohno, industrial engineer who revolutionized Toyota’s production system, leading the company to become one of the most important car manufacturers in the world over the years.

This method aims to reduce waste, particularly overproduction and excess inventory, by purchasing/producing only the pieces required to replace those that subsequent processes have required following real market demand.

This means kanban method can be classified as:

- Pull production methodology: production is externally “pulled” by the real market demand (and not by its forecasts) and internally by the pace of downstream production processes

- Lean production methodology whom philosophy focuses on minimizing waste.

The method includes practical rules for kanban card management (e.g. the card must be detached only when the container is emptied and consumed) and broader process optimization principles. For examples “Never pass on defective parts to the next process” and “Stabilize, rationalize, and simplify production processes.”

What is Kanban as Project Management Method (Kanban Method)

In 2007 David J. Anderson adapted the kanban method for software development and project management, calling it the Kanban Method or simply Kanban with a capital K.

The Method is based on a series of principles (e.g. encouraging small and continuous improvements as well as active participation of everyone in identifying possible changes) and practices. These include the need to limit work in progress (WIP) and visually manage workflows.

Important notice: the use of workflow visualization methods is an essential requirement but not sufficient to apply the Kanban Method in its entirety and effectiveness.

|

|

What is Kanban Board as Workflow Visualization Tool

A Kanban board, whether physical or digital, is a tool for visualizing and managing workflows i.e. is one of the fundamental practices (but not the only one) envisaged by the Kanban Method applied to project management.

It typically includes:

- Columns representing activity states (e.g., to-do, in-progress, completed)

- Kanban cards or Post-it notes representing tasks, moved between columns according to process stages. On each card there are the main information about the task e.g. deadline, responsible etc.

- Rules for applying Kanban Method principles, such as limiting WIP and Pull logic: according to this each collaborator “pulls” into the column of activities in progress only the amount that he/she knows can manage, avoiding work overload.

Kanban boards can be customized with additional columns, information, and elements like horizontal rows (called swimlanes) to separate activities by type, groups etc.

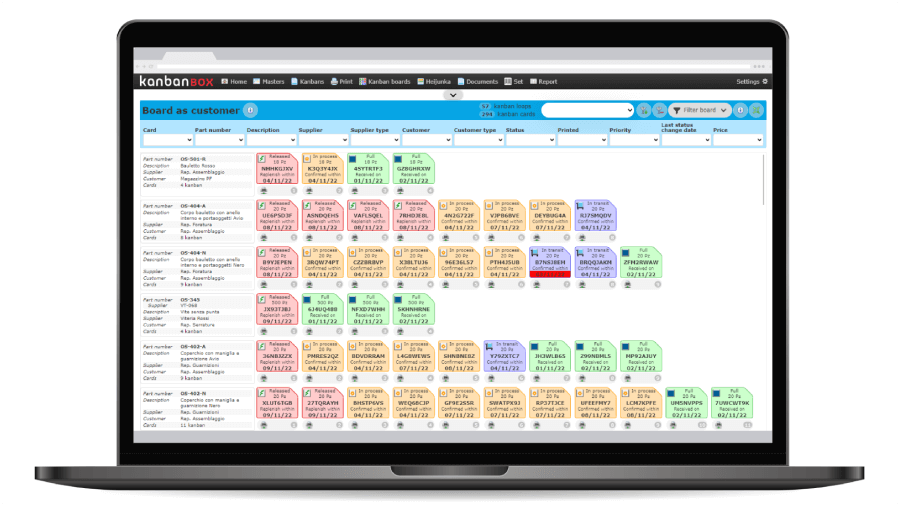

What is Kanban Software and E-Kanban Software

Software like Trello and Asana, often referred to as “Kanban software,” are inspired by Kanban boards but do not fully adhere to Kanban Method principles so they are not Kanban software.

In logistics and production, someone use the term “kanban software” to refer to tools for managing e-kanban but they are more accurately termed “e-kanban software” or “electronic kanban (management) software”.

KanbanBOX falls into this type of software as it allows you to manage e-kanbans, but it also offers additional functions for supply chain management and control. You can learn more about the advantages of KanbanBOX at this page. Or you can discover more about what is Electronic Kanban and how it work in this Guide.

Conclusion: what is kanban?

Given the numerous interpretations and uses of the word kanban, to avoid misunderstanding it is essential to specify the context by using terms like kanban card, kanban container, Kanban method, Kanban board etc. instead of simply “kanban”.

Now that you know the meaning of the word kanban, discover the advantages of kanban production management with this article.